How will the large-scale application of chiplets affect the semiconductor industry?

The advantage of chiplets is first of all to improve economic efficiency.

Chiplet reduces the impact of wafer defects on yield by integrating small-area chips, so it has significant advantages over large-area single SoCs in terms of overall economic benefits. In addition, Chiplet can break through the area constraints of a single chip and can perform heterogeneous integration. However, Chiplet has higher heat dissipation, power consumption and space requirements than SoC, so it is more suitable for chips with large computing power.

The world's leading system manufacturers are accelerating the industrialization of Chiplets, and the importance of unified interfaces and EDA tools has increased.

Leading chip factories such as #AMD, Intel, #Nvidia, Samsung and #Apple are gradually using Chiplet technology in chip design and manufacturing. At the design level, Chiplets can shorten the chip design process for system companies, but requires efficient on-chip network design and a unified interface protocol. At the same time, chiplet design also puts forward higher requirements for EDA tools, adding new functions such as thermodynamics and mechanical analysis.

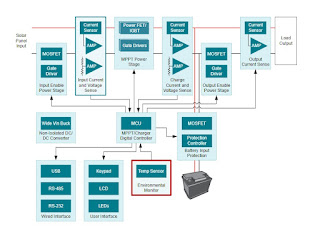

The complexity of chiplet manufacturing steps has increased, and the requirements for packaging processes, equipment, and materials have increased.

Because chiplet manufacturing involves photolithography, its production process is distributed in IDMs, fabs, and packaging factories. Therefore, there is a trend of gradual integration of front-end manufacturing and back-end manufacturing, and packaging and testing factories are expected to usher in a rise in volume and price.

In terms of equipment, the demand for photolithography, etching, electroplating, bonding and testing equipment has increased significantly; in terms of materials, in addition to the increase in photolithography materials, the amount of chip underfill materials, bonding adhesives, plastic packaging materials and packaging substrates, etc. improved.

Risk

Technology development is not up to expectations; downstream demand is not up to expectations; advanced packaging upstream raw materials and equipment imports are blocked.

Comments

Post a Comment